Turbine Wings

→ An algorithmic way to decompose three-dimensional solids into a 3-axis puzzle. With the use of 1mm plywood, material-saving, lightweight as well as stable bodies can be produced.

Wind Energy

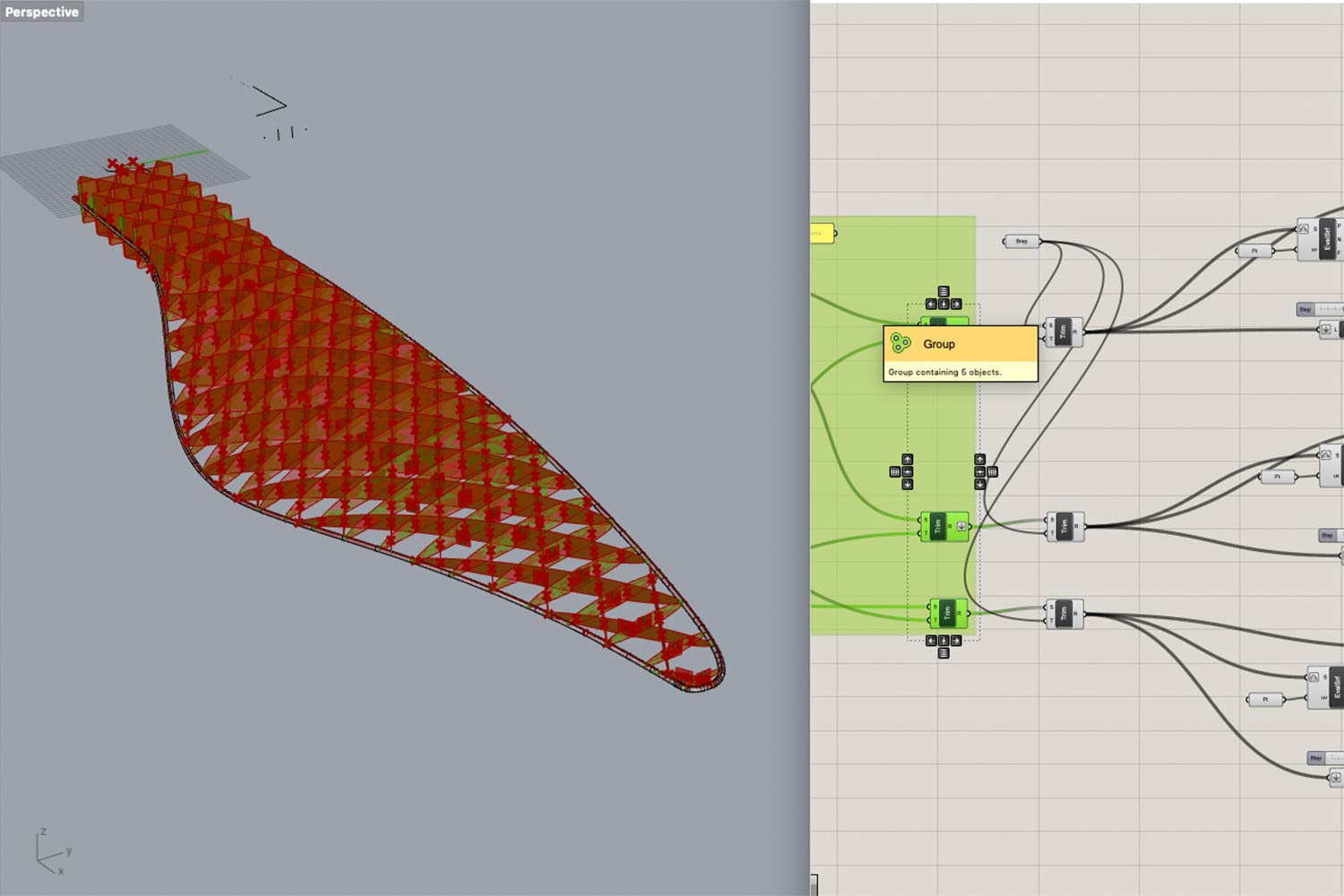

What does it take to produce your very own energy? We, a team of three students, were developing wings that would fit onto the mount of an electric generator. The objective was to come up with an interesting and replicable way of freeform model-building. With the help of Eva Kitting, the team and I developed a «Grasshopper» script that splits any freeform-body into three curvature approximating axes and generates a vector template that can then be lasercutted afterwards.

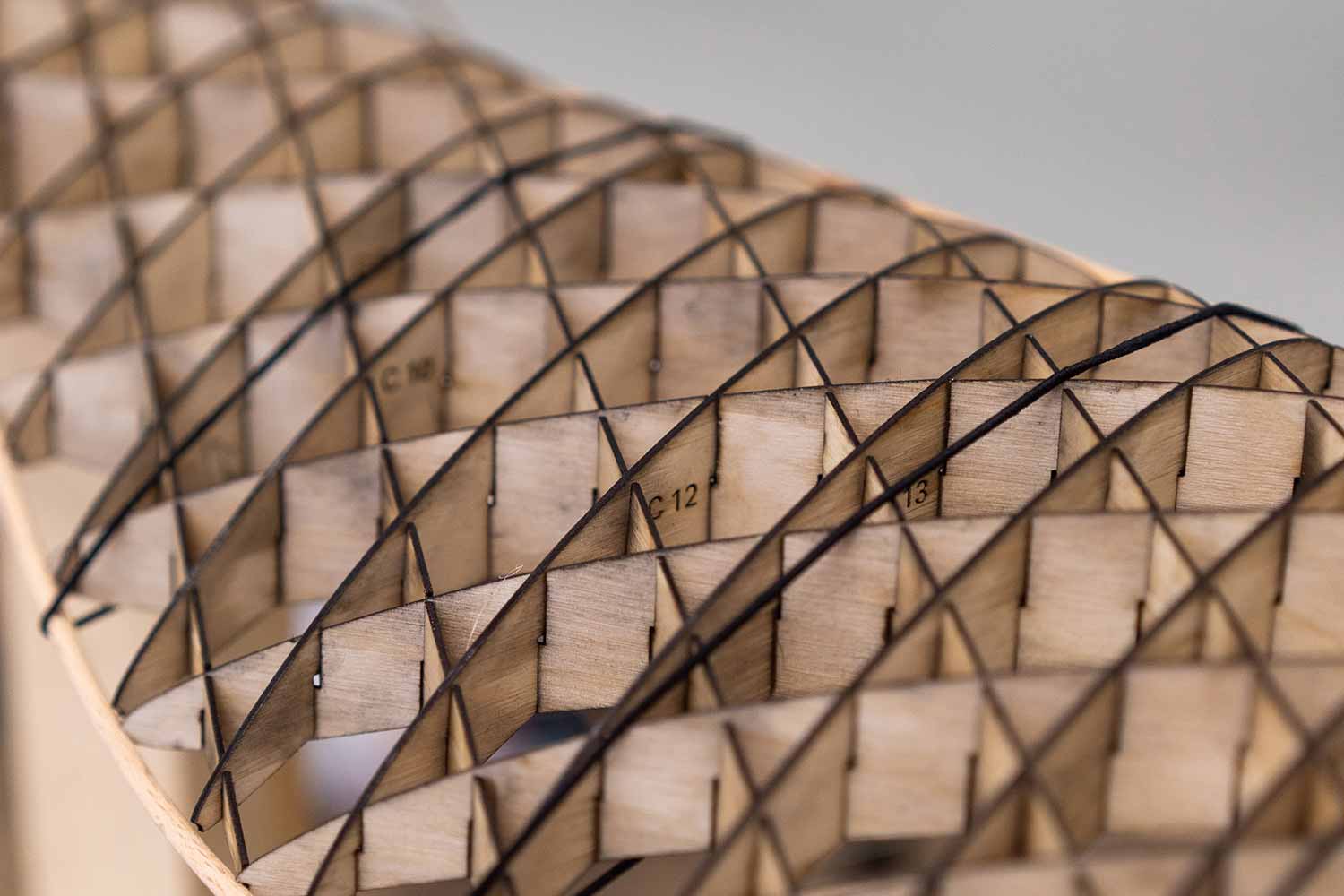

Assembly

After the individual ribs of the wing skeleton were cut out of 1 mm airplane-quality plywood, it was put together like a puzzle and we had the complete inner structure ready within 1-2 hours. Wooden rods were steam-bent to complement the outer contour of the wings.

Laminating

The finished interior was laminated with fiberglass and epoxy to provide sufficient contact area for the air. The strength and the lightness that resulted from the honeycomb pattern in combination with the epoxy-reinforced glass fiber was enormous.

Credits and Afterlife

The wings were co-created by Lucy Li and Pauline Laval. The finished turbine participated in a small exhibition at the University of Applied Arts Vienna, in which the six turbine designs resulting from the semester course were put to the test.